Concrete retarder, also called cement retarder, is a chemical additive that can delay the initial and final setting time of concrete. As we all know, in the process of concrete construction, the initial and final setting time of concrete is a very important indicator. Premature initial and final setting may cause the concrete to fail to be constructed smoothly, or cracks and other quality problems may occur.

The main function of concrete set retarder admixture is to delay the setting process of concrete by adjusting the reaction rate of cement and water in concrete. It can be added to concrete in a certain amount to slow down the setting time of concrete. In this way, more time can be spent on the construction and processing of concrete, improving the flexibility and efficiency of construction.

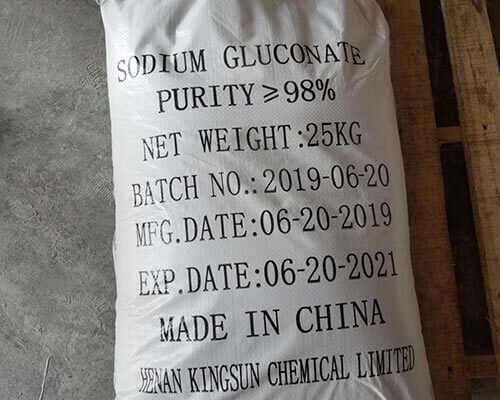

| Item | Sodium Gluconate (CAS 527-07-1) |

| Appearance | White crystalline powder |

| Purity % | 98 Min |

| Loss on drying % | 0.50 Max |

| Sulphate (SO42-) % | 0.05 Max |

| Chloride (Cl) % | 0.07 Max |

| Heavy metals (Pb) ppm | 10 Max |

| Reduzate (D-glucose) % | 0.7 Max |

| PH (10% water solution) | 6.2~7.5 |

| Arsenic salt(As) ppm | 2max |

| Packing & Loading | 25 kg/PP bag, 26tons in 20’FCL without pallets; 1000kg/Jumbo bag on pallet, 20MT in 20’FCL; 1150kg/Jumbo bag on pallet, 23MT in 20’FCL; |

Main Advantages of Concrete Retarder Admixture

Sodium gluconate retarder is an important concrete additive, and widely used in the construction industry. It has significant performance advantages, can effectively delay the setting time of concrete, and improve the workability and strength of concrete. The following is a detailed introduction:

- Significantly delay the setting time of concrete. The sodium gluconate retarder can significantly extend the initial and final setting time of concrete, providing a longer time window for construction. When the dosage is below 0.15%, the initial setting time of concrete can be delayed several times.

- Improve the workability of concrete. By delaying the setting of concrete, sodium gluconate improves the workability of concrete, making it easier to mix, transport and pour.

- Improve the uniformity of concrete structure. In large or heavy pouring projects, sodium gluconate retarder can avoid the formation of joints on the structure, enhancing the uniformity and integrity of the structure.

- Enhance the strength of concrete. When used in combination with an appropriate W/C ratio, sodium gluconate can reduce the W/C ratio and improve the compressive strength of concrete.

- Environmentally friendly and safe. Sodium gluconate is an excellent corrosion and scale inhibitor of polyhydroxycarboxylic acid type, which is non-toxic and harmless and environmentally friendly.

- In addition, concrete retarder admixture can be compatible with naphthalene based superplasticizer, aminosulfuric acid-based water-reducing agent, and air-entraining agent.

Reduce water-cement ratio and increase strength. Using sodium gluconate can reduce the water-cement ratio of concrete, thereby increasing the strength of concrete without increasing the amount of cement. This is especially important for high-strength reinforced concrete.

Improve concrete workability. Adding sodium gluconate can improve the workability of concrete, making it easier to pump and construct. In the process of premixing concrete and transportation, it is particularly important to increase workability and delay the initial setting time.

Reduce slump loss. In addition, sodium gluconate also has a significant slump-preserving effect, which can effectively reduce the slump loss of concrete and improve the stability and workability of concrete.

Application fields

As a concrete setting retarder, Kingsun sodium gluconate is widely used in the construction industry, especially in projects that require long working time or high temperature conditions. For example, in bridge projects in the Middle East, sodium gluconate has been widely used as a concrete admixture. In addition, it can also be used in electroplating, film manufacturing industry and other fields.

WHY CHOOSE KINGSUN COMPANY

As a leading manufacturer & exporter of concrete admixtures in China, Kingsun has more than 15+ years’ experience in construction chemicals industry. Our main products are sodium gluconate concrete retarder, SNF superplasticizer, PCE superplasticizer, sodium lignosulfonate and calcium lignosulphonate. What’s more, Kingsun has its own factory and raw materials, large warehouse, the advanced production lines and professional sales team. So we can provide high quality products, factory price and good services.

- Sufficient Supply: The annual output of Kingsun sodium gluconate retarder can reach 120,000 tons.

- Quality Certifications: ISO/BV/SGS certifications can ensure the qualified products and traceability.

- One-to-one Service: We can customize the order for your specific market and help you to save cost.

- Timely Reply: All the feedback from our customers will be treated seriously and promptly.

- Successfu Cases: Kingsun chemical products have been exported to more than 30 countries, they are

Pakistan, Bangladesh, India, Israel, Qatar, Bahrain, Mexico, Chile, Brazil, Turkey, Saudi Arabia, UAE, South Africa, Jordan, Russia, Peru, South Korea, Indonesia, Thailand, Philippines, Vietnam, Malaysia, Singapore,etc.